SSA

Battle tested precision.

Solid State Autoloader

The Solid State Autoloader replaces legacy electromechanical relays with ruggedized power electronics, delivering faster, safer, and more reliable round-chambering for main battle tanks.

With more than 600 units already fielded across multiple vehicle platforms, SSAL sets a new benchmark for high-current endurance and digital situational awareness inside the turret.

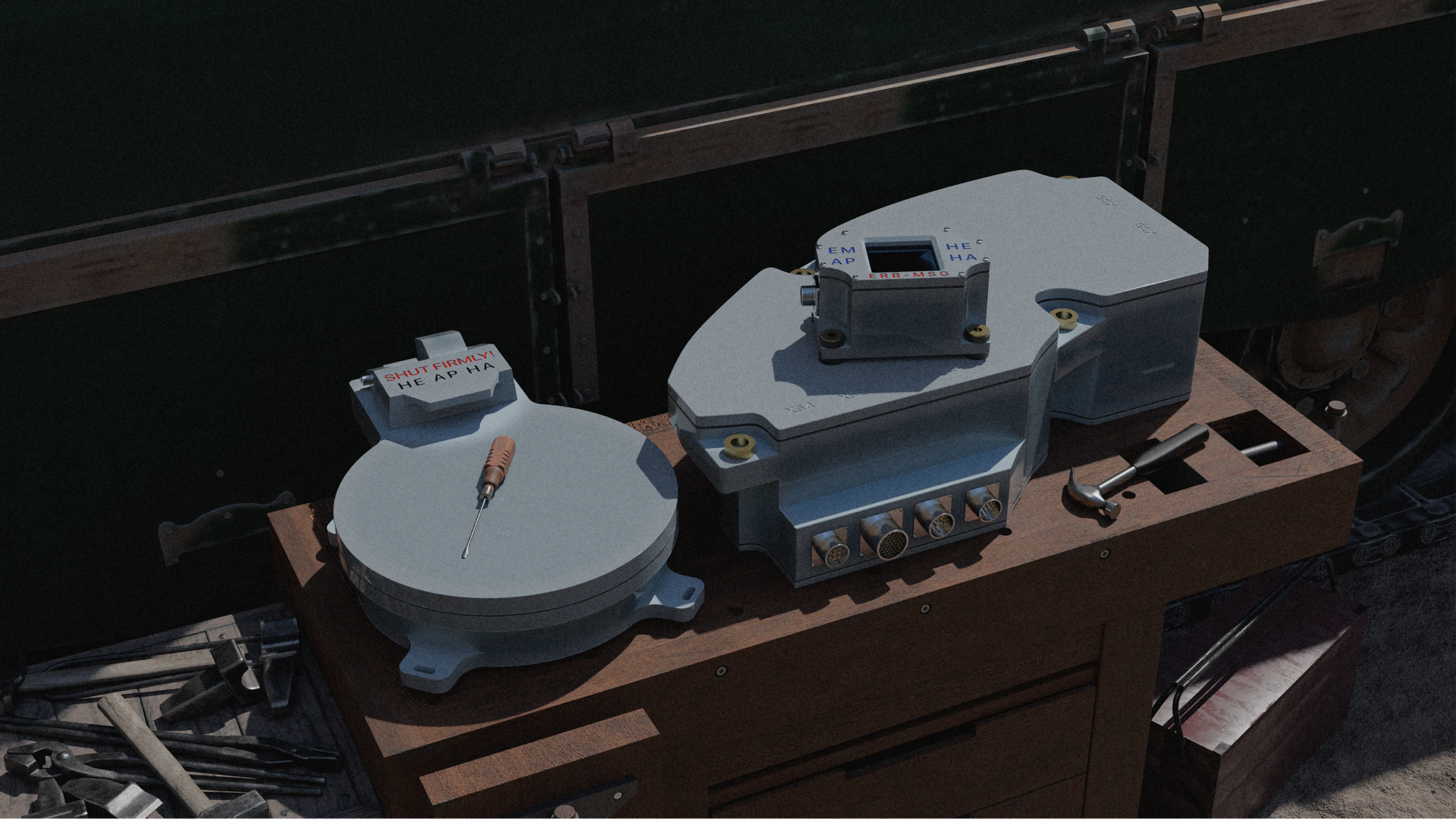

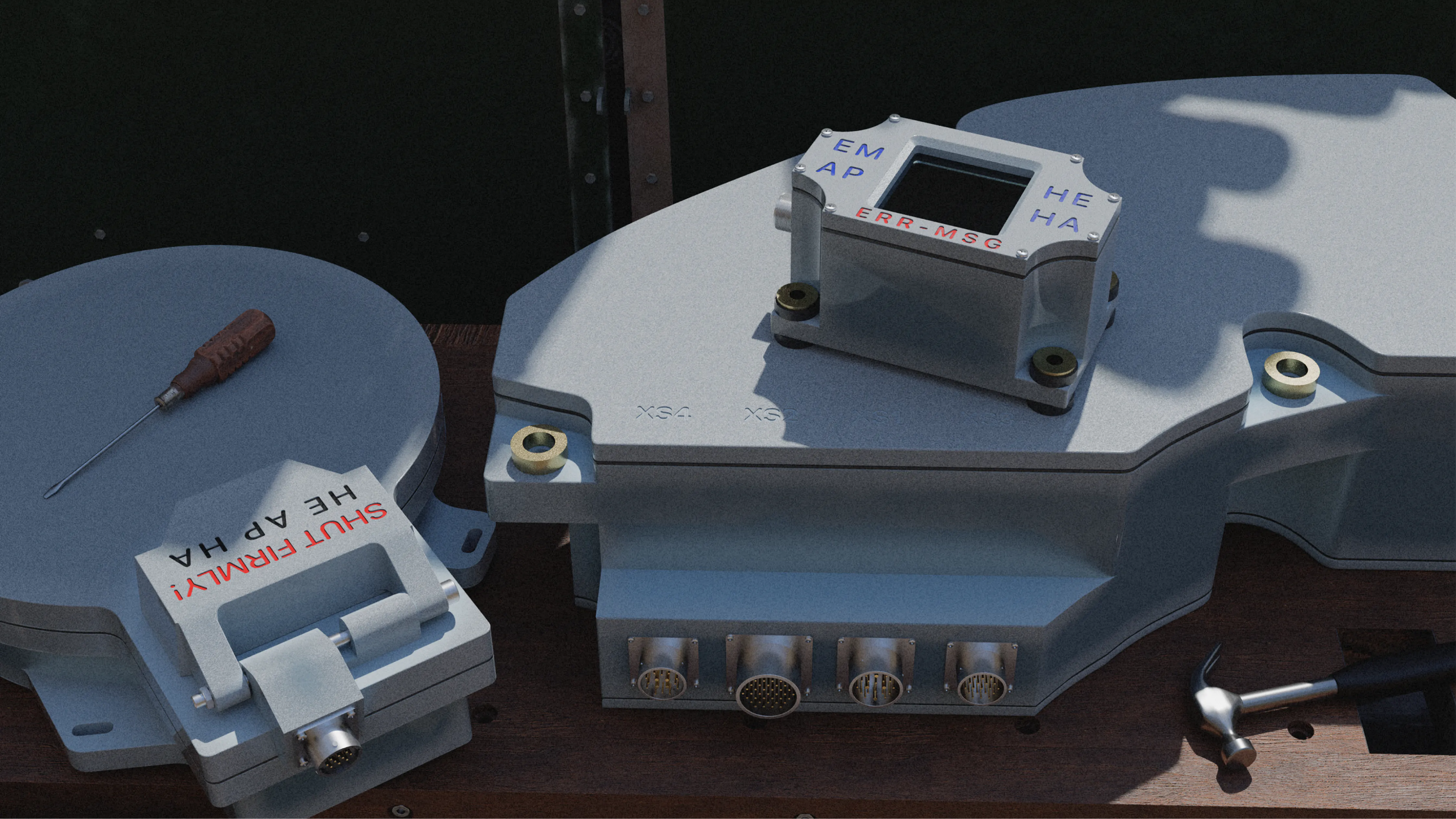

All–solid-state switching

Eliminates mechanical contacts—cutting misfire risk, reducing maintenance burden, and extending life cycles under high-current loads.

Digital operator display

Replaces analog gauges with a clear, back-lit interface that shows ammunition status, fault codes, and cycle counts at a glance—even under low-light or NVG conditions.

Smart memory & sensing module

On-board infrared sensors and non-volatile memory log each load sequence, enabling predictive maintenance and post-mission analytics without external data recorders.

High-current circuitry

Purpose-designed discrete devices withstand repeated surge currents from motor drives and power packs, maintaining cycle speed under extreme temperatures and shock.

Combat-proven pedigree

More than a decade of service and 600+ deployments confirm reliability across diverse climates and operational tempos.