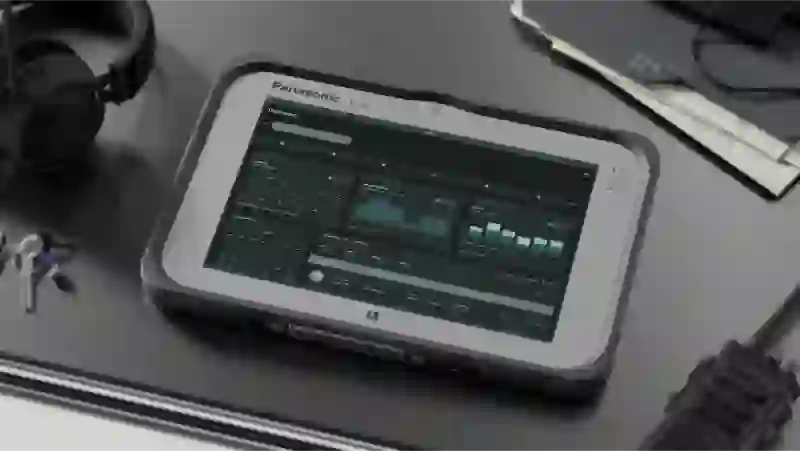

eMIA

Where coordination

meets confidentiality.

Private Enterprise Resource Planning

A mission-ready Enterprise Resource Planning and Manufacturing Execution System engineered for defense ministries, primes, and depots that cannot compromise on data sovereignty or cyber resilience.

Deployed entirely on customer-controlled infrastructure—even on classified or air-gapped networks—it unifies finance, supply, production, and maintenance while enforcing strict need-to-know access and verifiable auditability.

Sovereign, on-premise deployment

Runs inside accredited data centers or mobile command shelters with no dependency on public cloud—meeting national-security and classified-network mandates.

Zero-trust security architecture

FIPS-validated encryption, MFA/PIV-CAC, hardware security module (HSM) support, and continuous posture assessment protect identities, data, and machine-to-machine interfaces.

Need-to-know access control

Fine-grained RBAC/ABAC with mandatory-access controls (MAC) enforces classification, caveats, and releasability down to the record and field level.

Immutable audit & compliance

Append-only, WORM logs with time-stamps and chain-of-custody preserve evidentiary integrity for RMF/NIST 800-53, STIG, and national audit requirements.

Disconnected & contested-edge operation

Store-and-forward replication keeps bases and depots working when links are degraded; conflict-tolerant sync merges securely once connectivity returns.

Defense logistics & codification

Native support for NSN catalogue data, lot/serial/IUID tracking, hazardous-goods handling, and export-control attributes streamline procurement and materiel accountability.

Depot MRO & MES

Plan, execute, and record overhaul/repair with digital work cards, tool calibration, and quality controls; MES links to IoT sensors for real-time OEE and predictive maintenance.

Program-centric finance & contracts

Cost collection by WBS/CLIN, earned-value analytics, and milestone billing provide transparent control over complex, multi-year programs.

Interoperability & data portability

Open APIs and adapters integrate with PLM, SCADA, C2, and battlefield logistics; database-independent design (PostgreSQL, SQL Server, Db2, etc.) prevents vendor lock-in.