Cedule

Scheduling the

shortest route.

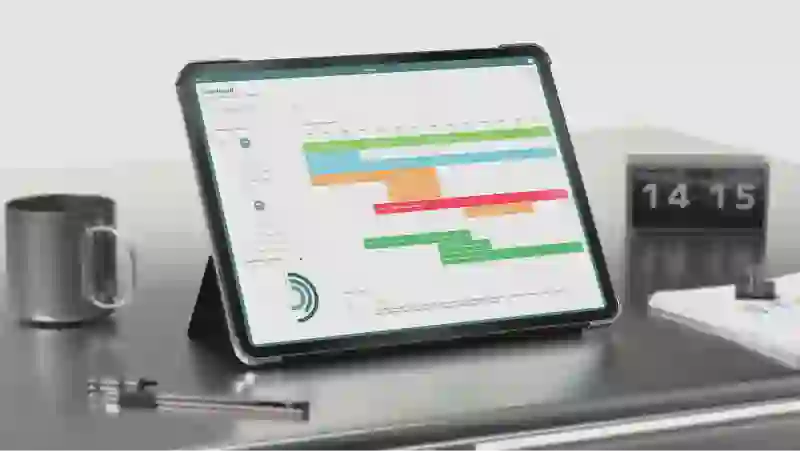

Job Shop Scheduler

Cedule connects every machine, sensor, and schedule on the factory floor—using realtime IoT data and machine-learning models to cut downtime, balance workloads, and elevate overall equipment effectiveness (OEE).

With Cedule, manufacturers gain a data-driven command center for the shop floor—turning raw signals into actionable insights that shrink downtime, smooth production flow, and lift productivity.

Always on equipment telemetry

Monitors run/idle states, cycle counts, and fault codes to deliver true machine up time statistics—not just planned availability.

Environmental sensing mesh

Edge nodes capture temperature, humidity, and vibration; contextual alerts prevent tolerance drift and scrap before it starts.

Live performance dashboards

Per machine KPIs and shift level heat maps refresh every few seconds, enabling supervisors to intervene before bottlenecks spread.

AI optimized job shop scheduling

Reinforcement learning engine sequences jobs against real time capacity, setup times, and due dates—boosting throughput without overtime.

Predictive maintenance analytics

Remaining useful life models flag bearings, spindles, and hydraulics weeks in advance, converting unplanned stoppages into scheduled service.

IoT based schedule enforcement

Digital work orders travel directly to machine HMIs; countdown timers and Andon triggers keep operators, planners, and robots in sync.