aGS

Scheduling

the shortest route.

Advanced Genetic Scheduler

aGS applies evolutionary search to the hardest scheduling problems—minimizing makespan, cutting changeovers, and lifting asset utilization across plants, fleets, and service networks.

By iterating through selection, crossover, and mutation, it converges on near-optimal schedules with minimal human input and adapts quickly as conditions change.

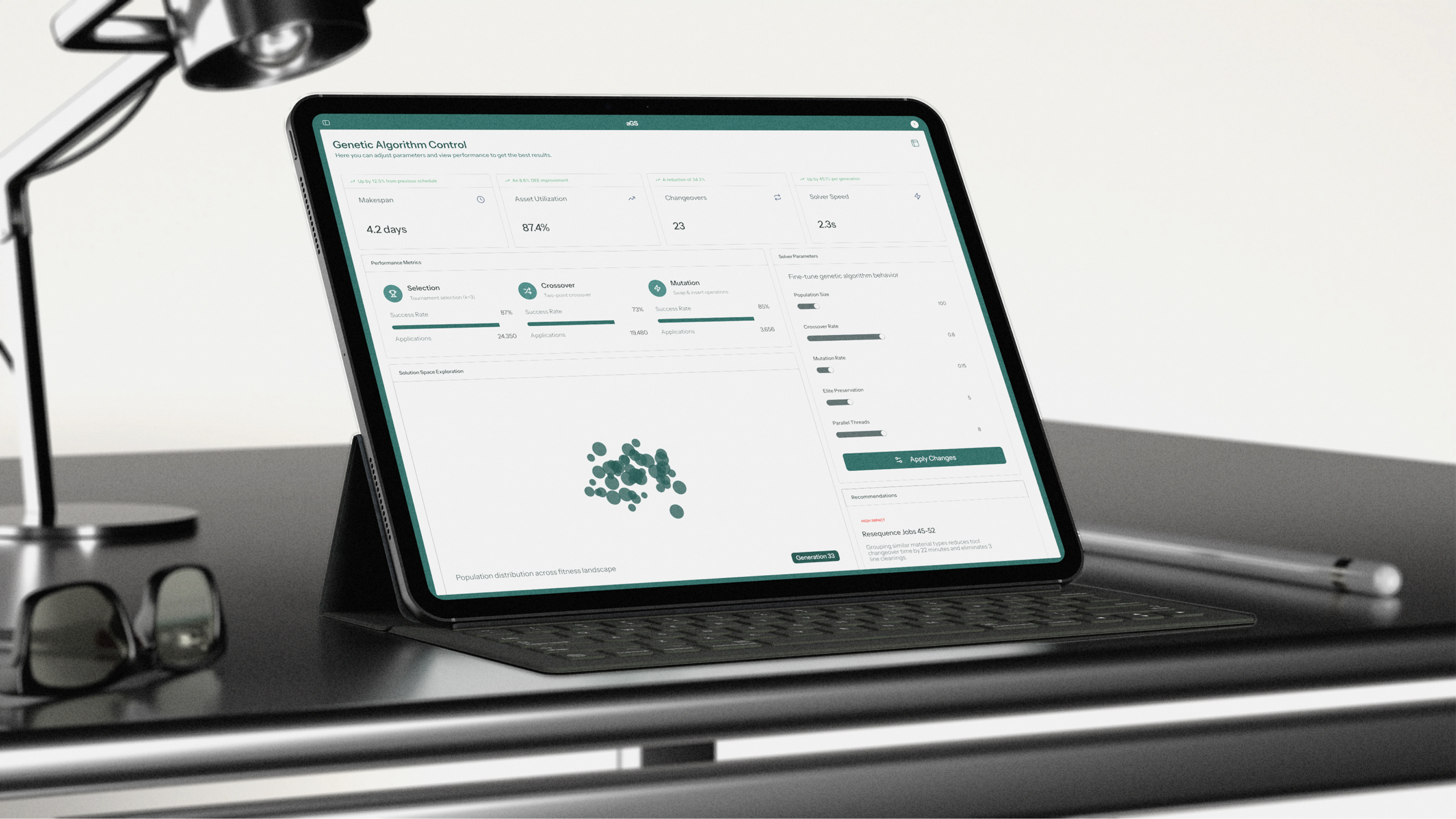

Genetic-algorithm optimization

Uses selection, crossover, and mutation to explore vast solution spaces and escape local minima—delivering shorter makespans and higher throughput.

Constraint-aware, multi-stage planning

Natively models setup times, skills, materials, and maintenance windows across multiple stages or machines, producing feasible schedules the first time.

Changeover minimization

Sequences jobs to reduce tool swaps and line cleans, lowering downtime and waste.

Resource-utilization maximization

Balances workloads across machines, crews, and shifts to raise OEE without overtime.

Dynamic re-scheduling

Reacts to rush orders, failures, or supply delays in real time, generating updated schedules with guaranteed constraint compliance.

Scalable solver architecture

Parallelized search handles large, complex instances—from single cells to multi-site networks—within practical run times.

ERP/MES integration

Bi-directional APIs ingest orders and constraints from existing systems and publish executable work plans back to the floor.

Explainable recommendations

Provides rationale and KPI deltas (makespan, setup time, utilization) for each proposed change, improving operator trust and adoption.